Ultrasonic Cross Correlation Flowmeter Measurements On-Power at Darlington NGS

Reactor Thermal Power at most nuclear plants around the world is determined by running a Heat Balance Program, which adds up all the heat sources and heat sinks around steam generators. Although by far the most important contribution to the heat balance is the feedwater flow into the steam generators , station instrumentation permanently installed to measure feedwater flow is normally uncalibrated before installation and is susceptible to physical degradation (fouling, erosion, etc.) and drift. One of the most accurate and inexpensive methods to verify accuracy of station flow instrumentation is to perform non-intrusive ultrasonic flow measurements. There are a number of ultrasonic meters available on the market, but only a few have been approved by nuclear regulators in different countries for feedwater flow calibration. WH Technologies has developed a next generation Ultrasonic cross-correlation flowmeter for use at Ontario Power Generation (OPG). Qualification at the accredited flow lab at the National Research Council in Ottawa was performed and software is undergoing quality assurance. After some research and development, an economical accurate non-intrusive ultrasonic flowmeter will be available so that other industries can take advantage of this powerful non-intrusive tool for situations where it is difficult to measure a flow accurately without cutting the pipes.

This flowmeter had been used at both OPG & Bruce Power plants to measure flows of different fluids such as water, heavy water, oil and liquid effluence in pipes with a range from 0.75 inches to 48 inches. It had many times helped the stations avert or delay force outages by providing flow measurement in systems that had no flow indications such as emergency water systems at Pickering and endshield cooling at Darlington.

Ultrasonic Cross Correlation Flowmeter - Rack mounted portable Nuclear Instrumentation

How it Works

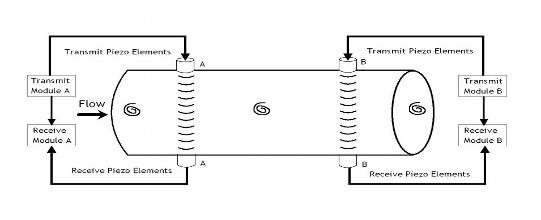

Two ultrasonic beams A and B are physically separated . Eddys from the turbulence in the flow modulates each of the ultrasonic beams. The modulated signals are processed and statistically cross correlated. The time difference is used to calculated the velocity based upon the known physical separation of the beams.

Transmit and Receive ultrasonic beams A & B on a pipe jig during qualification of the ultrasonic cross correlation flowmeter at the National Research Council (NRC) Hydraulics Lab

A row of ultrasonic cross correlation flowmeters housed in rack mounted portable Nuclear Instrumentation during qualification of the ultrasonic cross correlation flowmeter at the National Research Council (NRC) Hydraulics Lab

A machined frame design with multiple transducers aligned at different angles used at National Research Council (NRC) Hydraulics Lab, Ottawa, Canada. Cables connect to the transducer BNC

An alternative frame design with multiple transducer blocks aligned at different angles demonstrated in an application in Budapest, Hungary. The lower block has transmit transducers installed and hidden behind the pipe at 180 degrees are the corresponding receiver transducers. The upper transducer block is not populated with any transducers. Cables are then connected to the transducer BNC.